by TMW – Holden Wright Carpentry

Please contact admin@oftf.org.uk to register your interest.

Contact admin@oftf.org.uk to register your interest.

MODULES (20 Days off-site training comprising 4 x 1 week blocks over 12 months)

CITB launched the Skills and Training Fund in 2016 to help Small and Micro businesses invest in their people. Since its launch, the fund has delivered over £20m of funding to 4500 employers who are developing the skills of their workforce and improving their businesses as a result. Ongoing conversations with industry has led CITB to broaden the scope of the Skills and Training fund, expand the Fund to medium sized businesses, and offer the opportunity for Training Groups to submit collaborative applications to the fund on behalf of members. The new funds will be launched on 1st April 2020.

CITB is expanding the scope of the fund to pay for a wider range of training and skills development activity, and to place more emphasis on innovation and Management & Leadership training. The funds will support different forms of skills development (such as coaching or mentoring), and allow funding of training not currently covered by the CITB Grant Scheme (as long as projects meet certain requirements). This is alongside the continued support of grant-eligible construction sector training, with amounts of funding available still determined by staff numbers, and still paid in advance.

For Small and Micro employers this will mean an opportunity to explore how skills and training can positively impact your business – be that the use of technology and associated skills, or simply new initiatives and practices not previously implemented. It is up to you to determine what you need; OFTF and CITB are both here to support you.

For Medium-sized businesses this means an entirely new way to fund the new initiatives your business needs, and the ability to support transformational Management & Leadership training – an evolution that is a direct response to feedback from stakeholders across industry.

More information and fund guidelines are available on the CITB website. If you would like more information on how the OFTF is supporting members to be part of our collaborative application, please contact admin@oftf.org.uk

Two roofing courses were recently run at 16 King Street, Bristol which is, by the way, now also the registered address of the National Heritage Training Group. The first course was Regular Hip & Valley Roofing and the second course took this to a higher level with Advanced Roofing – Theory and Practice. These were both level 3 & 4 courses run by Alan Creasey who has a lifetime of experience in both contemporary and heritage roof construction techniques. A further advanced level course is planned for later in the year which will be a step-up to Complex Roofing. Alan also covers the history and development of roofs from Norman times onwards and infuses his delivery with many quirky historical facts and anecdotes which combine to make this course more entertaining than you might imagine it could be!

I have many years of experience of post and beam carpentry and also site carpentry and one of the most demanding elements of the craft for many people is the understanding of Euclidean geometrical theory applied to the construction of traditional roofing. For me the first course was a refresher in the setting-out of hips and valleys on regular roofs but it was also aimed at others in the group who had no experience of this type of roof layout. There are many books on the subject illustrated by many accompanying diagrams but they are no substitute for a course such as this where, as a group, you can work together under expert guidance to demystify some of the complexities involved.

The first week comprised theory sessions which investigated the mathematics of the trigonometry used in calculating the angles and lengths of the main roof timbers. This cumulated in a summary table of information which could be used to cut the roof in the workshop or on-site. With this information we went on to build a scale model of a hip and valley regular roof with a dog-leg gable feature.

During the second week we applied similar albeit more complicated geometry to the construction of a regular pentagonal 1.25 spire with jacks and purlins. To give some perspective the hips of our model were around 1.6 metres long.

I would certainly advise completing the first course before embarking on the advanced course. This point was also emphasised by the tutor who clearly understood that during the first week you develop a good basic grounding in the geometry and in the second week you build on this knowledge – with the assumption that you have grasped the geometry and the pace is a little quicker.

These courses are becoming rarer due to the commitments of the current tutor but if you do get the opportunity of getting your name down for the next ones I and many other fellow carpenters who have done it would recommend that you do so in order to increase your confidence and ability in this specialist area. Courses are advertised on the Carpenters Fellowship & Oak Frame Training Forum websites & social media.

The courses are run by the OFTF & supported by the CITB & NHTG

Jeff Storer Feb 2020

Bristol Timber Framing Company Ltd

Llys Llewellyn (welsh for Llewellyn’s Court) is intended to be a reconstruction of one of the five royal residences that were in use in Wales in the early part of the 13th Century. Sadly none of these buildings has survived. The Carpenters’ Fellowship UK, working alongside the archeology experts of the Museum have created a design for this timber and stone building based on evidence from contemporary surviving wooden halls.

The construction is to be undertaken by a core team of CF members but other CF participants will be given the opportunity to get involved at the stage immediately prior to the site erection of the building.

All participants in the course will have the opportunity to contribute to the fabric of this unique building which will be a spectacular living history resource for many generations to come.

In our regular series of interviews with members of The Carpenters Fellowship – we talk today to Nigel Howe. Nigel responsible for training the timber framers of the future. Phew. Not too much pressure then……

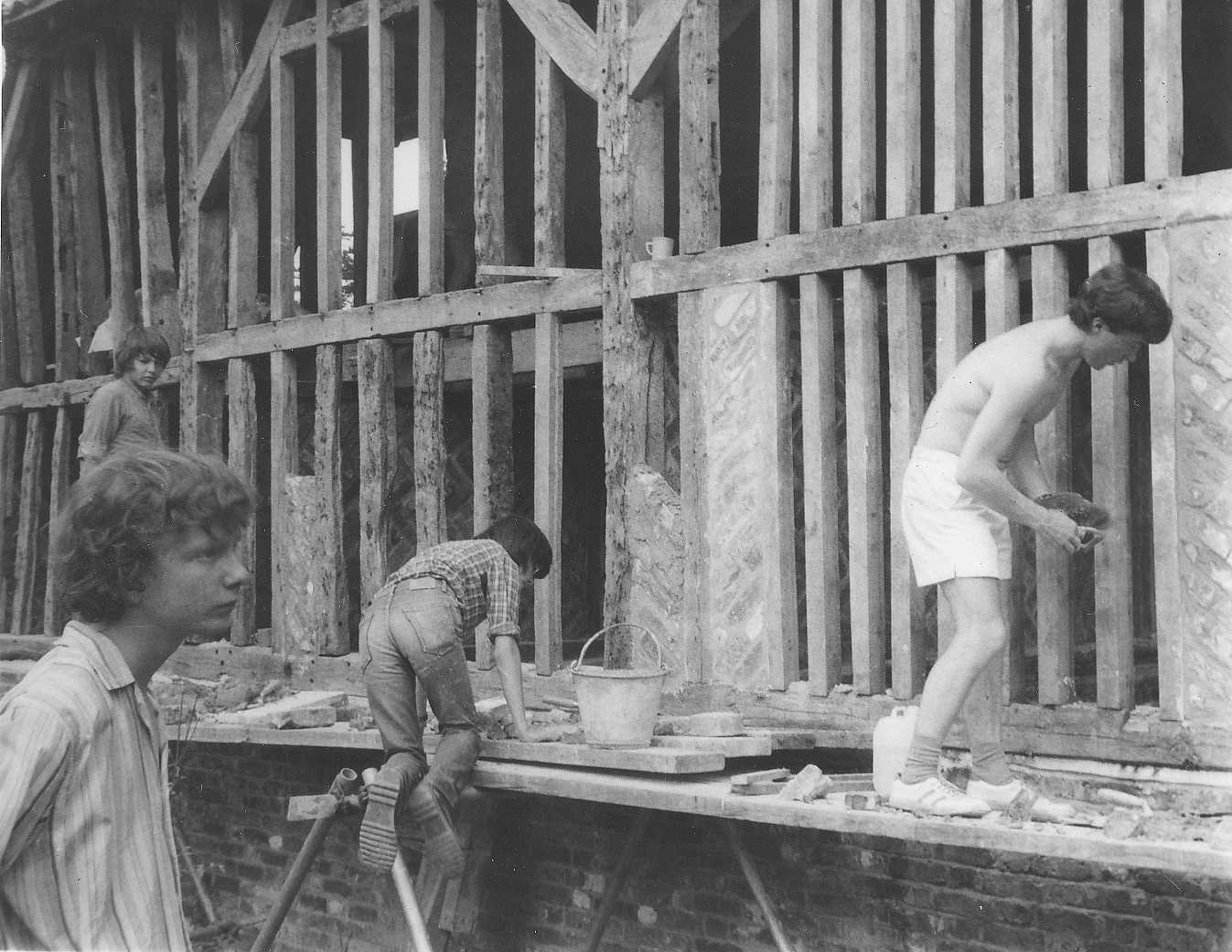

My father was part of a self-build project in the 1950s that built 50 homes, all 3 bed semi-detached with garages & long gardens. So I grew up among tradesmen who built their own homes, conservatories, sheds, greenhouses. Over the years I learnt how to dig foundations, lay bricks, measure, level, triangulate & work with timber. My school was a Secondary Technical School (boys) specialising in the Building Trades in Reading Berkshire. As part of the curriculum, we built extra workshops on the site & built an outdoor pursuits centre in the Wye Valley where we spent weeks at a time. There I developed my skills in Technical Drawing TD, & Woodwork. In particular. Part of the idea of the school was to train the architects & craftsmen, & the building inspectors for the area. The school was a tough mixture of Hells Angels, skin‘eds, swots & hippies with a mutual respect for our building skills & sporting prowess. There were 14 of us in the Berkshire U15 Rugby squad of 30.

I moved to Bristol, married Jackie & trained in to be a teacher. Wherever we have lived we have built, extended, repaired & maintained properties. We have taken on derelict & almost uninhabitable properties & raised our children amongst sawdust, lime mortars, linseed oil & the smell of log burners.

20 years ago I left mainstream teaching & helped set up the Forest of Avon Wood Products Cooperative along with Jim O’ & Rupert. I worked on the Leigh Woods Barn Project & a 3 bay open barn at Chelvey Court & decided to buy a Wood-Mizer mobile sawmill. I took on the lease for the redundant farm buildings at Chelvey & set up the Chelvey Designer Makers Cooperative of woodworkers. I worked with Henry Russell & Gudren Leitz, & met Charley Brentnall, on the Westonbirt Arboretum Great Oak Hall project. Every timber went across the Wood-Mizer & we did 12-hour shifts to keep ahead of the framers. This build was instrumental in the origins of the CF & we photograph our new SAP intake with John Russell’s model of the Great Oak Hall.

Timber framing is heavy demanding work & requires the rare ability of engaging brain, eyes & hands to work with a variety of tools in all weathers & ground conditions. We are all mad; some quietly behind the drawing board & others barking in the framing yard.

I have been fortunate to have worked on several inspiring projects which in their own ways have played a part in shaping me (mainly my hands, knees & back). The Chelvey Court barn shelter, Penny Brohn Cancer Care centre garden shelter, the OFTF buildings reflecting the training of the CF members. The one project that must rank as the greatest challenge in so many ways & therefore the most inspiring & depressing must be Timber House.

The transformation of a Grade II* Listed building that had been derelict for many years. 16 King St Bristol. A jetted 4 storey Jacobean merchant’s house built circa1663 in the period of the Restoration of the monarchy after the Civil War. So from Restoration 1660 to restoration 2014-17.

The building shows all the signs of wear & tear & changes over the centuries. When we took it on the previous leaseholders had done major repairs to the roof & cellar but ran out of steam. When we took it over there were a few original ceilings & floor joists but no floors. The work has been a combination of repairs & restoration alongside upgrading to comply with up-to-date standards of thermal & acoustic insulation & other building regs for fire & structural engineering requirements.

People who have worked on Timber House include: Jo, Sarah & Rob; Henry, Pete, Alan, Jeff, Marius, Finn, Sam, Mark, Will B, Ant, Will R, Tom C, Ollie, Tim H, Reza, Brendan, Tommy, Will, Finley, Graham & other helpers & support from Sheila, Amy, Freya & Heidi.

This has been a monumental task & has emphasised that balance & compromise that face us all when dealing with our heritage “What to leave in & what to remove?” Wherever possible we” leave in” to be rediscovered By future craftsmen & investigators. If we remove we are making a value judgement on what is worthy.

Now that the building regs have been signed off & it is being used Timber House has been given another chance to stand proudly in the historic heart of Bristol.

One in which I can sit down with a glass & a book!

One where the grandchildren can play among some of the Oak sawdust that I have brought in from the workshop. A home where Jackie is happy surrounded by her artwork. Probably with a view of the sea on the North coast of Cornwall so that the sea is blue. I haven’t seen it. I don’t know if it exists or whether I have yet to build it.

How did you start your career in Timber Framing?

My first taste of vernacular building came when I was at primary school. We had a trip to the nearby Weald & Downland Museum, where they had recently finished the frame of the now iconic Bayleaf Farmhouse, and were working on the wattle & daub infill panels. We got to work on the daub, which was, of course, delightful and exciting for us 8-year olds!

But it was a few years later, just after Christmas in 1980, when as a former pupil and neighbour of Bedales School in Hampshire, I was contacted by my old woodwork teacher to ask if I would help out with a project they were working on at the school.

The school had developed an ‘Outdoor Work’ department – a small-holding – to give the pupils opportunities to work with plants and animals. The had been given a Victorian timber framed barn, which had been dismantled and was awaiting re-erecting on the school grounds. I was called in to help with the foundations. It was freezing and wet, but great fun, barrowing loads of concrete into collapsing trenches! It so happened that the carpenter in charge of the project was one Charley Brentnall. We got on, and I loved the work, so asked Charley if I could help him in the school holidays. So I got to work on some of Charley’s earliest barn projects. When I finished my A-levels, I went to work with Charley full-time in my gap year.

At the end of my gap year, I went to York to study Psychology. This led me away from timber-framing for a few years, but by a very circuitous route, I came back to Charley in 1989, and was introduced to Carpenter Oak (which I thought was a nickname for Charley, as he hadn’t told me about the business!).

Charley was looking to develop the ‘Woodland’ part of Carpenter Oak & Woodland, and I enjoyed making shingles & pegs, so took on the development of ‘Woodland Products’. I enjoyed running this for 15 years, until in 2004, I left to start my own little company, Greenwood Direct.

One of our first framing jobs turned out to be a roof frame for a burned-out cottage in the New Forest, which was featured on Grand Designs! I got to meet Kevin McCloud a few times during the filming, and invited him to speak at Frame, to which he agreed!

What is the biggest challenge within the Timber Framing world?

The ageing workforce – framing is a hard physical job, and most people I know have been doing it a long time. The OFTF is doing a great job to help develop new framers through its Special Apprentice Programme, but our culture needs to rebuild respect in craft skills.

The availability of good quality oak. It seems we are all relying on oak from the continent, as UK forestry doesn’t seem to be producing enough suitable quality timber. This makes us vulnerable in terms of supply and costs.

The economy – the crash of 2008 caused long-term damage to the building industry, and Brexit could do the same.

What is the most inspiring project you have worked on?

I’ve often wondered if my love of timber buildings came from the experience of working on the Bayleaf as an 8-year old. I’ve certainly always found the Weald and Downland Museum an inspiring, almost spiritual place to visit.

But I’d have to say that the Gardener’s Shelter at Cressing Temple answers this. Partly because of Laurie Smith’s beguilingly beautiful daisy-wheel design, with its geometrical echoes of the magnificent 12th century Barley Barn, just a few yards away, but mostly because of the experience of its creation. Hewing oak beams from the round, converting them all by hand and scribing the frame, all with no tape measures or power tools, with a group of superbly enthusiastic and fun people was not just a great pleasure, but a genuine inspiration.

Where/what is your dream home and why (feel free to send us some pics!)

I consider myself extremely fortunate to live in a house I love, in a beautiful part of the world, but in a fantasy world, I would love to live in mediaeval splendour in the aforementioned Bayleaf, preferably with modern hygiene and medicines!

This month we are chatting to Rupert Newman who is on the board of Directors at The Carpenters Fellowship. The Carpenters Fellowship is a not for profit organisation. Set up in 1998 The Carpenters’ Fellowship was formed with the aim of: promoting communication, training and sharing of knowledge amongst those interested in historic and contemporary timber framed structures.

Rupert runs Westwind Oak in North Somerset and is also the author of ‘Oak-Framed Buildings’ which is a practical book on the technique of timber-frame construction for carpenters, builders and aspiring self-builders, but also a source of inspiration to anyone who appreciates beautiful buildings. You can get a copy of the revised edition from Westwind Oak.

I started working for a village carpenter at the weekends when I was 12. When I was older I got into building roofs, then repairing old roofs. This led on to working with green oak and building new roofs. That was 28 years ago!

Mainly people! Shrinkage too!

Building a bridge with a 60-foot clear span across a river and the first house I built in the Alps on the side of Lake Annacy.

My dream home would be in Cornwall by the water. Like the one I built at Mylor Creek.

One word: WOW